A real-world experiment

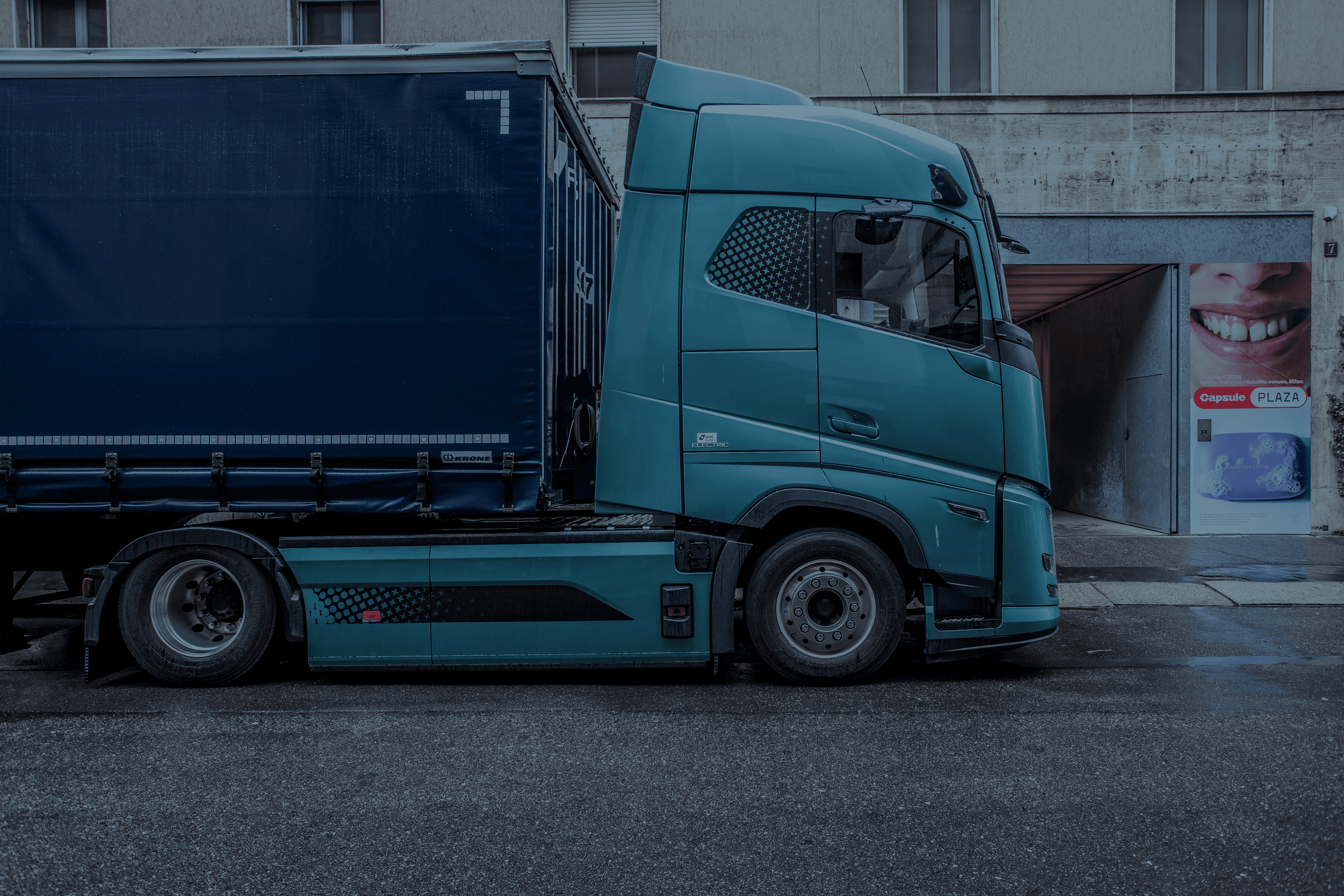

We hear a lot about cutting emissions, and we have to recognise that the transport sector has a significant footprint. We figured the best way to understand the challenge wasn't just talking about it, but by rolling up our sleeves and giving it a proper go. So, we embarked on a bit of a real-world experiment: a long-haul electric truck journey. Think about it – getting goods across Europe usually means diesel, lots of it. We wanted to see if we could genuinely run a near-zero emission service, not just on paper, but on actual roads, facing actual hills and occasional charging station headaches.

The mission

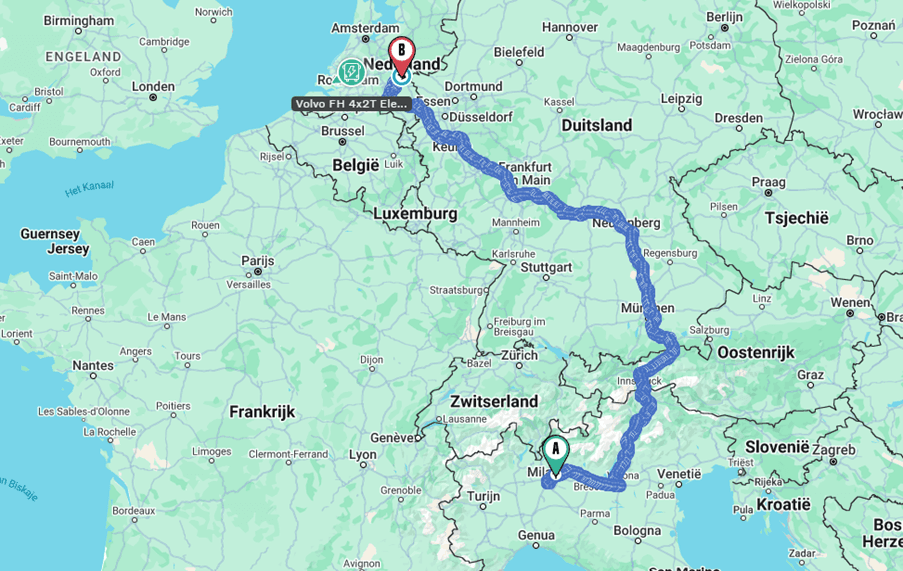

Recently, we teamed up with Hydro and Volvo Trucks to pilot a long-haul, fully-electric transport service from Eindhoven to Milan—and back—demonstrating that near-zero-emission logistics over continental distances is not only possible but increasingly practical. The service was to transport 5 tonnes of new design furniture crafted from the world’s first aluminium made entirely from recycled post-consumer waste, for Hydro’s “R100” exhibition at Milan Design Week. Hydro wanted to turn sustainability into action by demonstrating the possibility of reaching net-zero emissions by 2050, not only through optimizing the production process, but achieving near-zero emissions even for transporting products to the Milan Design Week.

More than just a truck trip: why this matters

This wasn't just about seeing if a battery could last the distance. It was bigger than that. Transport makes up a big chunk of global emissions. And while electric vans and local delivery solutions are finally hitting their stride, long-distance heavy-duty transport still has a long way to go. But it can’t wait. If we’re serious about reaching net-zero targets, we must start now. This trip wasn't only about reducing emissions, although we were hoping to do that. It was about stress-testing what’s possible today with the tech we have, the roads we share, and the challenges we’ve got to face head-on. Our industry needs to change, and pushing the boundaries is how we figure out the how. We set out with a few key aims:

Near zero: could we keep direct emissions almost non-existent for the whole trip? That was the big one.

Testing the tech: how would current electric trucks and planning tools actually cope with a demanding, long-distance route? We needed to validate the strategies.

Learning curve: what works? What doesn’t? We needed to capture real lessons – driver experiences, charging gaps, does it actually work operationally?

Sharing is caring: be open about the challenges and the solutions. No point keeping it secret; we all need to learn together.

Sparking change: hopefully, projects like this encourage more investment in charging infrastructure and supportive policies. Building the future, one brick upon another, you might say.

It’s all about continuous improvement. Learning what’s working and, just as importantly, what still needs a bit of effort.

Plotting the course: not your average road trip planning

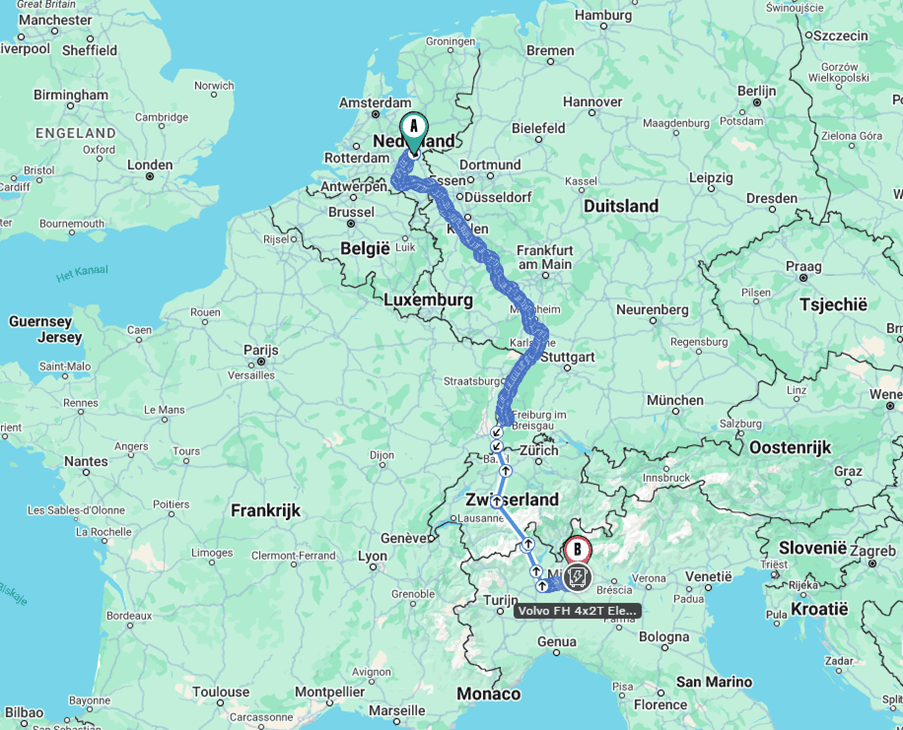

Planning a 3,000 km round trip in an electric truck isn't like just punching a postcode into your satnav. You need serious preparation. We used a planning system (Volvo Connect) to map out potential charging stops and get a handle on energy consumption along the route. Every hill, every potential traffic jam – it all feeds into the calculation.

The outbound journey

For the trip to Milan, we actually decided to incorporate a train leg through Switzerland. Why? Crossing the Alps chews through energy, and the train offered a practical way to manage that, especially on the outbound journey when timing for the Design Week was key. The truck and driver hopped on the train in Freiburg, Germany, and rolled off in Novara, Italy, ready for the final stretch. It’s about finding the smartest mix. All in all, the road part covered just over 750 km, using about 752 kWh of energy. That works out to an efficiency of just over 1 kWh per km.

From Eindhoven to Milan

Day 1, 170km: from Nijmegen to Mönchengladbach in Germany via Eindhoven, where the cargo was loaded.

Day 2, 488km: from Mönchengladbach to Freiburg Im Breisgau. In Freiburg the truck plus trailer was loaded onto a train that crossed Switzerland and took it together with the driver to Novara (Italy).

Day 3, 55km: From Novara, where the train arrived at 4:30 AM, the truck drove the final leg to Milan.

Facts from the road: Road distance 750.18 km Energy consumed 752.26 kwh Efficiency 1,0027 kwh / km |

The return journey

Coming back, we decided to test the truck on a full road route via the Brenner Pass. This wasn't just for kicks; it was about gathering more data on an all-road scenario, considering factors like cost and charging schedules that made the train less ideal for the return this time. The return trip clocked up nearly 1450 km entirely on the road, consuming around 1255 kWh. Interestingly, the efficiency was slightly better on the return at about 0.87 kWh per km.

From Milan to Eindhoven

Day 1, 413km: from Milan to Brennero (Italian/Austria border) with a charging session in Verona and one more on arrival.

Day 2, 741km: from Brennero to Bad Honnef (Germany). 2 charging sessions during the day and one on arrival.

Day 3, 292km: From Bad Honnef to Wijchen via Eindhoven.

Facts from the road: Road distance 1446.68 km Energy consumed 1255.33 kwh Efficiency 0,8677 kwh / km |

Let's talk challenges: it wasn't all smooth sailing

So, what did learn from our epic eTruck journey? Pioneering isn't always easy. We definitely hit a few bumps – or perhaps, charging hurdles – along the way.

Charging hiccups: finding reliable, fast chargers suitable for a big rig isn't always straightforward. We encountered stations that wouldn't accept our credit card (seriously?), forcing us to push on to the next one. Not ideal when you’re watching the battery percentage. And not all stations had the speedy chargers we needed.

Rest vs. recharge: Drivers need breaks, trucks need charging. We tried syncing mandatory rest periods with charging stops. Sounds efficient, right? Well, sometimes the required rest time was longer than the charging time, leading to slight delays. Plus, you can't always leave the truck plugged in overnight at a public station, which can make it difficult for the driver to get their proper rest.

Range realities: Hills and cold weather can drain the battery faster than you'd like. We saw this on the Brenner Pass – range dropped quickly going uphill in chilly (1°C!) conditions. But here's the flip side: going downhill, the truck regenerated a significant chunk of energy. It's a different kind of driving dynamic.

The round trip riddle: One of the biggest operational headaches right now is the lack of a widespread network for long-haul electric trucking. This often means the same driver and truck have to make the return journey, even if the truck is empty or there's a long wait. Finding another load locally just isn't realistic yet. This trip was a perfect example: our driver, Jan, had quite a gap between dropping off in Milan and picking up for the return. He actually had to fly home to the Netherlands and then fly back to Milan to drive the truck with his cargo back. So those flight emissions are taken into account in our overall calculations for the trip. It highlights the inefficiencies we need to solve as a network develops.

Selfie recording of Jeroen van Wensen (BU Compliance Manager at DFDS), showcasing the eTruck at the charging station.

The bottom line: did we save emissions?

Absolutely. While the main goal was testing feasibility and learning lessons, the emissions savings were significant. Even factoring in Jan's flights back and forth, we saved nearly 470 kg WtW CO2e compared to doing the same trip with a standard diesel truck. And here’s the really exciting part: if we could guarantee that all the electricity used for charging came from renewable sources (which is the ultimate goal), the saving jumps to a whopping 1760 kg WtW CO2e. That’s a potential 76% reduction compared to diesel for this route! Still including flight emissions. It shows the massive potential when green energy meets electric transport. The theoretical emissions savings potential would be huge, once a long-distance electric transport network is developed.

So, what's next on the road transport decarbonisation journey?

This Milan trip was just one step, and we won’t pretend this one pilot is enough, but still a really important one.

It proved that long-haul electric transport is possible, even with today's infrastructure challenges. It gave us invaluable, real-world data and highlighted exactly where improvements are needed – better charging networks, optimised routing, etrucks with a longer range. This trip showed us that the barriers aren’t technical—they’re logistical, regulatory, and infrastructural. We're committed to sharing what we learn. Because decarbonising shipping and logistics isn't something DFDS, or any single company, can do alone. It requires collaboration, innovation, and a willingness to try new things, even if they seem daunting at first. The journey to zero emissions is, well..., a journey. But with every new kilometre driven, we're getting a clearer map of the road ahead.

Behind the wheel: a chat with Jan, our driver

Who better to ask about the experience than the man himself, Jan Elsinghorst? We grabbed him for a quick chat.

A quiet ride: The first thing drivers notice? How quiet and relaxed it is compared to a diesel. Less vibration, less noise – makes for a less tiring day.

Charging practicalities: Does the trailer need to come off for charging? Mostly, yes. Only a couple of spots allowed charging while coupled. Luckily, many car charging spots can be accessed by a truck, sometimes requiring a bit of ‘inventive’ manoeuvring, as Jan put it. You make it work!

Performance: How did it handle? Pretty well, actually! Even on the tough Brenner Pass climb, performance was good. And as mentioned, it recouped a lot of energy downhill.

Time taken: Surprisingly, Jan reckoned the whole round trip didn't take that much longer than it would have in his usual diesel truck. The charging stops balanced out somewhere along the line.

The honest verdict (for now): If emissions weren't a factor today, would he choose electric or diesel for a long trip like this? "To be honest, for now diesel," Jan admitted, purely because of the range achievable within current driving time regulations. But he quickly added a crucial point: "When 600km range trucks will come, you can actually do the same with eTrucks as with diesels." That future isn't far away.