Challenge

Navigating troubled waters

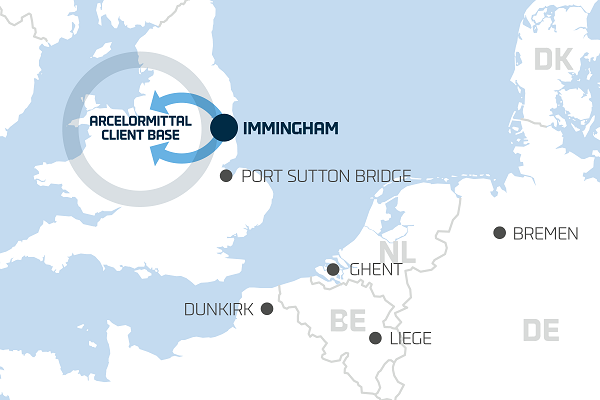

ArcelorMittal faced some frustrating logistical issues shipping their steel coil from the Continent to their customers in the North West of England. East coast ports such as Port Sutton Bridge have capacity limits due to low water and a lack of trucks able to carry steel coil west.

Solution

One facility, many opportunities

To solve the issue, we recommended ArcelorMittal take advantage of our steel terminal in Immingham. It’s the ideal solution to meet their high-volume shipping needs as our wide range of assets on site ensure a high level of flexibility and safe handling.

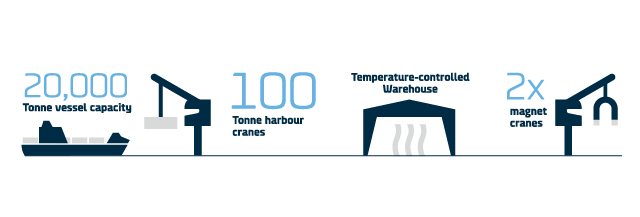

Two 35-tonne capacity magnet cranes minimise the risk of damage to coils during unloading and loading, while easy access to rail and road ensures hassle-free shipping onwards.

The Immingham terminal accommodates vessels up to 20,000 tonnes – considerably more than the smaller east coast ports. It also features 100-tonne capacity harbour cranes, a heated warehouse and a highly experienced team available seven days a week to assist ArcelorMittal when needed.

A smooth, co-ordinated process

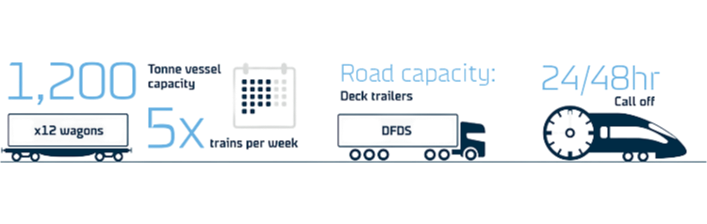

This is how it works: We orchestrate the shipping of ArcelorMittal’s steel coils to the port and move them to the warehouse, or directly onto our road and rail assets as requested on 24/48 hour call off. We ship off 4-5 trains a week, each carrying up to 1,200 tonnes of steel coil on 10-12 wagons. Additionally, we have road capacity in Immingham to ship coil on trucks with well deck trailers.

Results

Higher volumes, less risk

ArcelorMittal have steadily increased their volumes since making use of the Immingham steel terminal. One significant advantage for the company is the terminal’s magnetic cranes which minimise the risk of damaging the coils.

“Because we use magnetic cranes for handling the coil in our warehouse, we have a very low level of damage to the coils. With the demands of the automotive industry, there is a zero tolerance towards damaged coils, so these low damage rates are very important, not only to ArcelorMittal, but across the supply chain.”

- Ian Penistone, Operations Director, DFDS