Flexible deliveries keep Volvo cars on top

ArcelorMittal Belgium is a highly innovative and fully integrated steel producer with plants in Ghent, Geel, Genk and Liège. Part of the ArcelorMittal group, the largest steel producer worldwide, the Belgian operation ships more than six million tonnes of flat carbon steel a year to customers around Europe, including most of the automotive manufacturers.

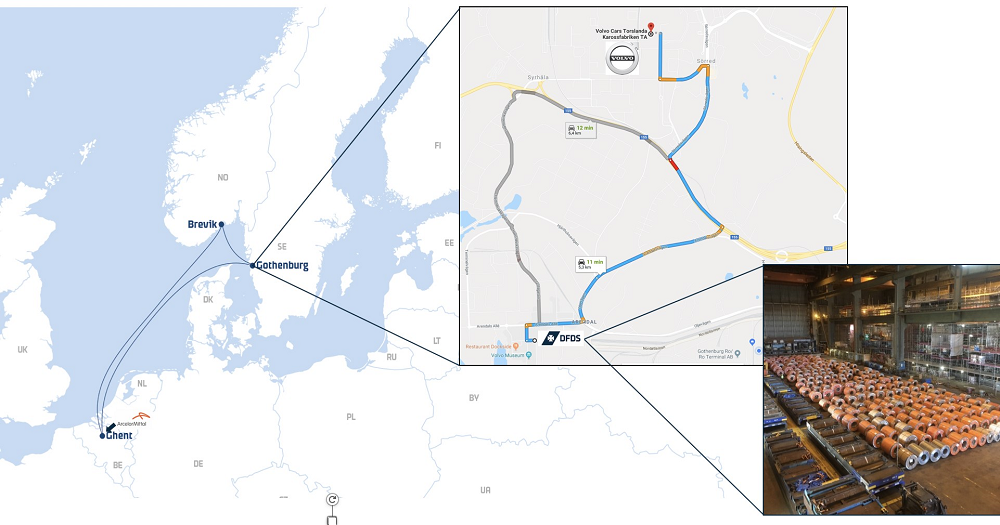

One of ArcelorMittal’s major customers is Volvo, which has six production facilities in Europe, including the Torslanda plant located in Gothenburg, Sweden. The Torslanda plant is Volvo’s largest plant producing approximately 300,000 cars a year.

The Ghent-Gothenburg connection

DFDS has been transporting ArcelorMittal steel to Volvo’s Torslanda plant since 2006. Every day, DFDS transports steel coils, weighing five to 20 tonnes each, from the Ghent port to the Gothenburg port on bulk ro ro vessels – up to 600 tonnes of steel per week. Once the steel arrives in Gothenburg, it is stored in DFDS warehouses until it is called off to production. DFDS then loads the trailers with the specified coils for just-in-time delivery to the plant, five kilometres away.

“Volvo orders steel of different thicknesses and qualities primarily used for the car’s body,” says ArcelorMittal’s Maritime Logistics Manager Tom Logé. “Each week, they specify the items they need and sometimes they have urgent requests. That’s where DFDS brings its A game.”

Keeping materials flowing

DFDS runs eight departures a week between Ghent and Gothenburg and if a coil is urgent for Volvo, they make sure the coil ships on the next departure. If the vessel leaves in the morning, it can be there the next day. This makes life easier for Kaj Tervakoski, Volvo’s supply chain coordinator, who needs to make sure the right materials are on hand at the plant at all times.

“DFDS is also very flexible on our side,” says Kaj. “I can call them at any time, and they will deliver the exact coil we need from the warehouse – sometimes within the hour. They are always looking for new ways to improve the flow of our stock to help optimise our production. It’s great to have partners that are truly interested in being responsive and improving your business.”

8 departures per week between Ghent and Gothenburg

Crossing time: 32 hours

See more about the schedule here

| Departure | Arrival | |||

|---|---|---|---|---|

| Mondays | 1230 | Tuesdays | 2300 | |

| Tuesdays | 1400 | Wednesdays | 2100 | |

| Wednesdays | 1400 | Thursdays | 2100 | |

| Thursdays | 1400 | Fridays | 2100 | |

| Thursdays | 2200 | Saturdays | 0900 | |

| Fridays | 2200 | Sundays | 1500 | |

| Saturdays | 2200 | Mondays | 0700 | |

| Sundays | 2200 | Tuesdays | 0700 |

Read more articles

Read more about DFDS and news from many different industries we support.