Challenge

Transporting steel from all production stages

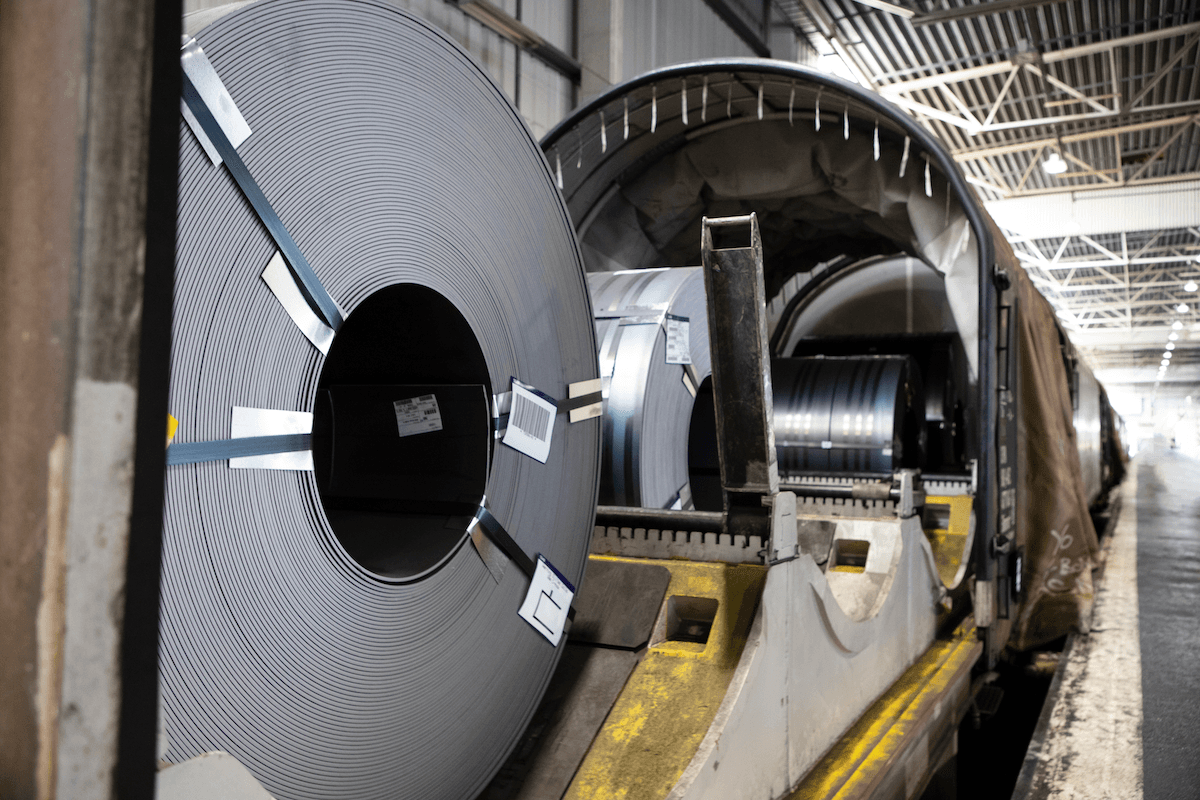

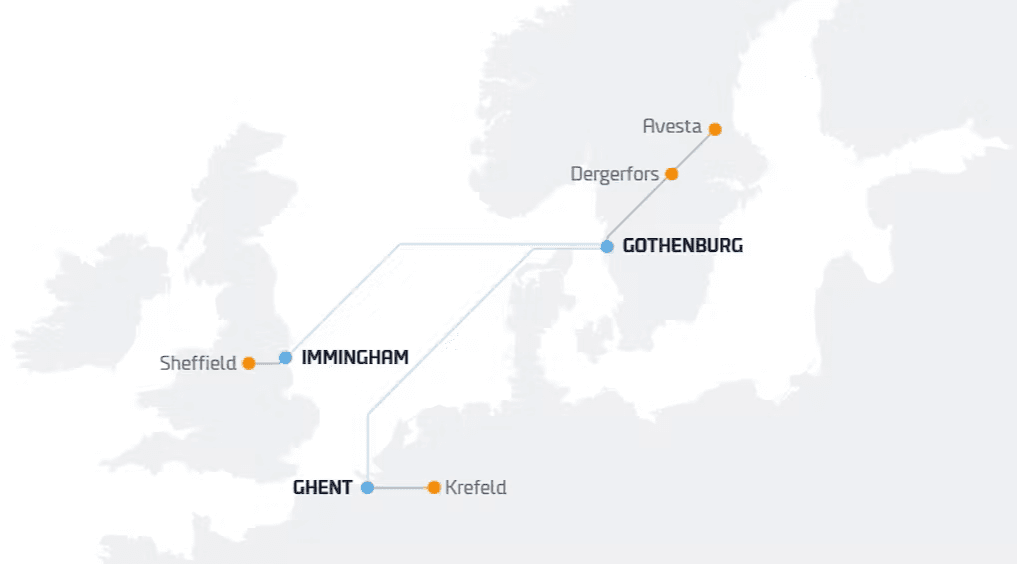

Outokumpu needed a transport solution capable of moving crude stainless-steel products in varying stages of the production process between their mills in Sweden, the UK and Germany. These mills are located in Avesta, Degerfors, Sheffield and Krefeld. To optimise reliability and cost throughout production, the solution needed to be flexible and allow for full-load shipments.

Solution

An intermodal system tailored to specific needs

We worked closely with Outokumpu to develop a fully customised intermodal system where dedicated equipment is always on reserve at key ports and freight terminals across our European network.

200 dedicated intermodal flats

One of the solution’s key features is that Outokumpu can benefit from more than 200 intermodal flats that are available at any time. These provide a great deal of flexibility as flats can be transported via rail and sea and have been purpose-built by DFDS for transporting steel products.

Results

Reduced lead and shipment times

The new intermodal system and daily departures have helped reduce lead times and the ability to send rush orders when last minute shipments are required.

Outokumpu also benefit from specialist steel handling equipment at DFDS ports, including a 100-tonne crane in Immingham, UK, while a straddle crane in Gothenburg has further reduced shipment times.

"The service, flexibility and reliability of the solution provided has proven over the past years and allows us to quickly react on any changes within our supply chain."

- Ronald van Dodewaard, SCM Transport Manager for Europe, Outokumpu